The fluctuation in the input prices including the construction sector where SCI is operating has caused the certain impacts on the Company's production and business activities. However, with various attempts, SCI believes to partly control the input supply sources to avoid interruptions and helps insurance of the quality and progress of the works.

The global economic situation is under complicated development due to the post-Covid-19 pandemic. The recent conflict between Russia and Ukraine is made the situation worse by the entirely negative effects around the world. As the economic field is concerned, the sanctions between countries are still ongoing causing many businesses to the struggling that indirectly caused the supply chain disruption, pushing the input prices of various commodities to skyrocket, especially the price of construction materials.

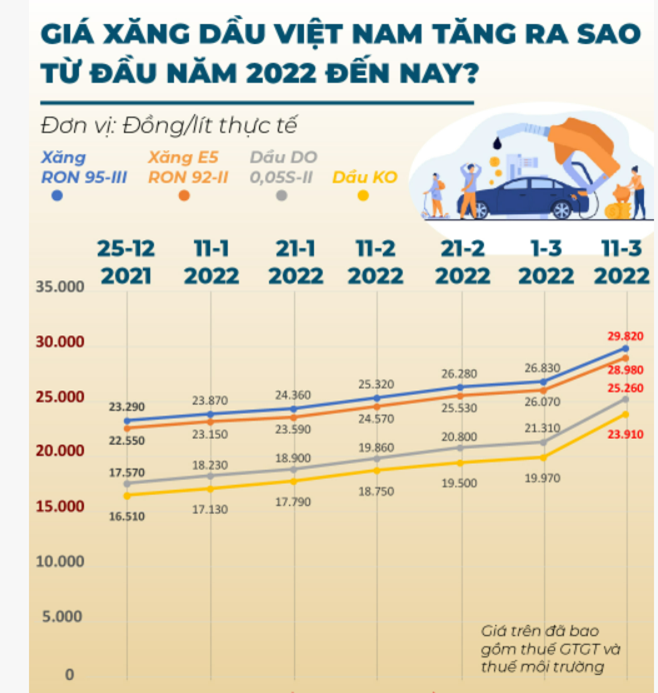

From the end of 2021 so far, the prices of key commodities such as iron, steel, cement, fly ash for SCI’s local and abroad projects have increased significantly (mostly from 30% above). In Laos, the average fuel price in May 2022 is LAK 17,476, increased by 6,945 kip/litter as compared to January 2022 (LAK 10,531), equivalent to an increase of 66% compared to the beginning of the year. The domestic market (the price of Zone 2 is considered) also witnessed a similar situation when the average fuel price in May 2022 (VND 24,191) increased to VND 6,982/litter compared to January 2022 (VND 17,209), equivalent to an increase 41% compared to the beginning of the year. The oil prices are expected to continue escalation in the near future

The sharp increase in the oil prices has caused the record skyrocket in the domestic and international transportation costs, especially by sea (besides the issues caused by lack of empty containers due to the global logistics chain disruption by the impact of the Covid pandemic) putting the pressure on procurement mission for the Company's procurement department. In particular, with the re-emergence of the Covid-19 epidemic in China which resulted in many provinces and cities in this country being blocked or restricted, causing many difficulties because numerous project goods were purchased from this country. The congestion at the border gates due to the impact of China's Zero-Covid policy by enhancing the customs supervision at the border gate area also puts the pressure on the Company's goods supply, especially in terms of progress.

For the ongoing projects, it is the difficulty in sourcing the materials, labour, machinery and construction equipment caused by the above reasons, For the lump sum contracts, the package contracts, the failure to be adjusted the Contract an increase/decrease or no additional payment caused by the above price fluctuations shall more or less affect the Company’s revenue and the project profit compared with the expected. This is an issue facing all construction businesses in general and SCI in particular and need to find a way to overcome.

With an effort for the Investor’s benefit and the goal to ensure the construction quality and the committed schedule as the top priority, SCI has been implementing a number of measures to minimize and limit the above-mentioned impact on the Company’s production and business activities. As said by Ms. Mai Thi Van Anh, Deputy Director of SCI E&C, the Company is currently implementing a number of measures to limit the impact of material prices as noted below:

- Review and strictly control the supply and logistics system to ensure the highest efficiency in goods circulation (both domestic and imported);

- Sign the procurement contracts for ongoing projects as soon as possible to fix input prices, avoid the large fluctuations and bind the fixed price contractual terms;

- Improve the procurement staff qualifications to ensure the initiative and the working accuracy, avoid the over-/under-purchasing and over/under-supply for the financial optimization &human resources;

- For fuel used for the Company's machinery and equipment system (DO 0.05S oil, auxiliary oils, gasoline, etc.), strengthen inspection and supervision to avoid loss, maintain and control the machinery operation to make full use of the fuel consumption to create the highest output with the most optimal fuel level;

- Make periodic forecasts and give necessary warnings to the relevant departments for improving the information communication level, so that the parties have a comprehensive and complete view of the market situation of the products accounting high market proportion, high importance or high demand to update the bid package price at the appropriate level of redundancy. For the packages offered with price increase conditions, a corresponding warning to the investor and adjustment is made when contract requirements are satisfied. For all-inclusive, fixed-price packages, tightly control all cost items to minimize the impact of overall price fluctuations;

- Negotiate with the suppliers who have signed the principal contracts and regularly suppled the goods to minimize price increases based on the principle of sharing, for long-term cooperation;

- Balance the financial resources, actual demands and the specifics of preservation to increase inventory for a number of frequent goods such as iron and steel, spare parts for machinery and equipment;

- For the goods at risk of being affected by China’s blockade or travel restrictions and by other exporting countries where the Company is working with, conduct negotiations with suppliers to find alternatives. If required, conduct an evaluation to select an alternative supplier meeting the price, quality and schedule criteria (with the sourcing report to the Investor if any) or change the transport plan in case of traffic jams at the border gates;

- Enhance the capital collection in line with the progress to ensure the cash flow for production and business activities and meet the demand for the goods back up;

- Increase observation of fluctuations in the foreign exchange market, the world and the domestic monetary policy to perform the financial operations using hedging tools such as signing contract on forward and future options etc… to make full use of the foreign currency sources.

With the above solutions, SCI believes to partly well control the input supply to avoid disruption helping the production and business activities maintained effectively. Accordingly, the projects will be guaranteed in terms of the schedule and quality, and the Company’s targets on the revenue and profit shall not be under great pressure.

With the great determination in maintaining the business reputation, keep looking for opportunities in the challenges, SCI believes to overcome such difficult period, continue to become the worthy partner for the Investors’ trust and selection.